All About Positive Displacement Pumps

We’ve covered the differences between centrifugal and positive displacement pumps, but how much do you really know about the latter? Let’s dive deeper into the world of positive displacement pumps and what you need to know about them.

The Basic Characteristics of Positive Displacement Pumps

Most pumps fall into one of two categories: centrifugal pumps and positive displacement pumps. Due to their simplicity, centrifugal pumps are generally more common. However, positive displacement pumps are more adaptable and diverse. They provide a continuous flow regardless of pressure and can typically handle more difficult conditions than centrifugal pumps. Positive displacement pumps are preferred in any application where high pressure output, low flow rate, or accurate dosing is required. Plus, they can run at any point in the pump curve.

Positive Displacement Pump Types

Positive displacement pumps can be very adaptable and therefore well-suited for various jobs and set-ups. Keep reading for more insight into how positive displacement pumps work and what different types are available on the rotating equipment market.

Screw Pumps

Screw pumps have the highest flow rate out of all the positive displacement pumps. Therefore, they are commonly used in applications that require high-intensity viscous liquids such as oil production, fuel transfer and injection, and irrigation. They operate in an axial pumping motion as fluid moves between screw threads on two or more rotors. As these screws rotate and mesh, the fluid is displaced axially, reducing turbulence.

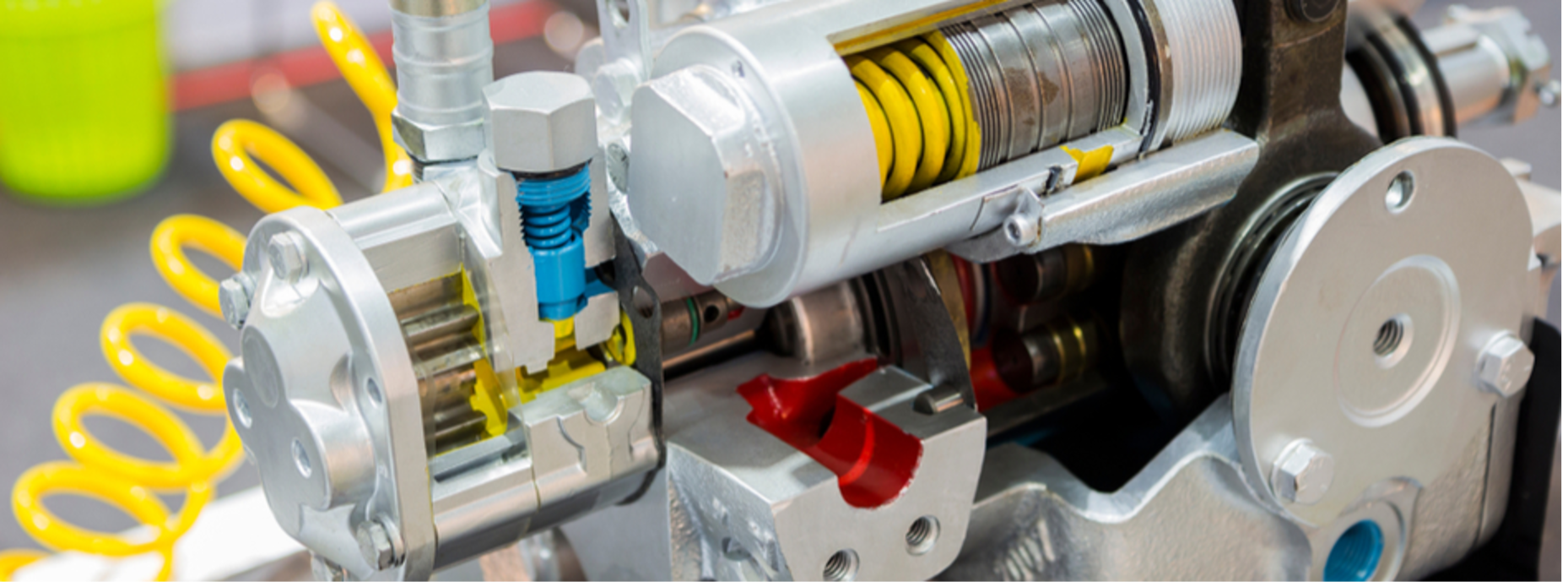

Plunger/Piston Pumps

These pumps use a piston or plunger to force a liquid through the pump. They can achieve extremely high pressures, making them a desirable option in many industries and applications. Plunger pumps are often used for the highest pressure operations, reaching as much as 10,000-30,000 psig. Typical applications include high pressure washing, paint spraying, oil production, and others involving low viscosity liquids.

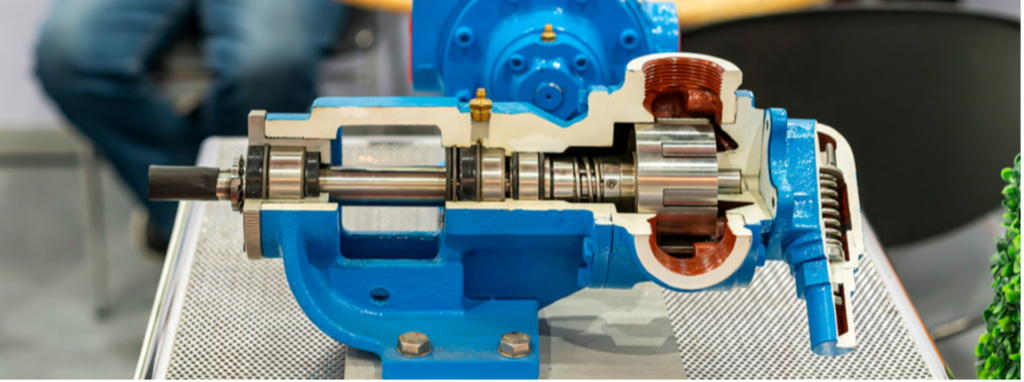

Rotary Gear Pumps

Rotary gear pumps are used in various industries and services. They are made to pump clean fluids that are otherwise not suitable for centrifugal pumps. In addition, because they do not typically handle solids well, they require the viscosity of a liquid to lubricate the idler and driven gears to prevent premature wear from metal-to-metal contact.

Air Operated Double Diaphragm Pumps

Air operated double diaphragm (AODD) pumps are among the more versatile types of positive displacement pumps. They are shear sensitive, self-priming, and inherently explosion-proof. In addition, they require compressed gas to power the pump rather than an electrical motor. This allows them to be used in situations where an electrical pump is not suited, for instance, when pumping flammable liquids.

Vane Pumps

A vane pump is a self-priming positive displacement pump that provides constant flow at varying pressures. A relief valve is built in to prevent the pump from building to a pressure that may cause vane wear. Their unique design allows them to be resistant to entrained solids. Vane pumps are used in applications that involve low viscosity fluids, such as fuel loading and transmission, automotive transmission systems, drink dispensers, and more.

Sealless Pumps

Some positive displacement pumps do not have a dynamic seal where the pump shaft penetrates the pump casing. This is referred to as a “sealless” pump. Sealless pumps can be either canned motor designs or magnetically driven. Sealless pumps serve many purposes, but they are primarily used for pumping toxic or volatile liquids in situations where leakage cannot be tolerated. At DXP, our manufacturers’ sealless pumps are designed and built for precise performance and longevity.

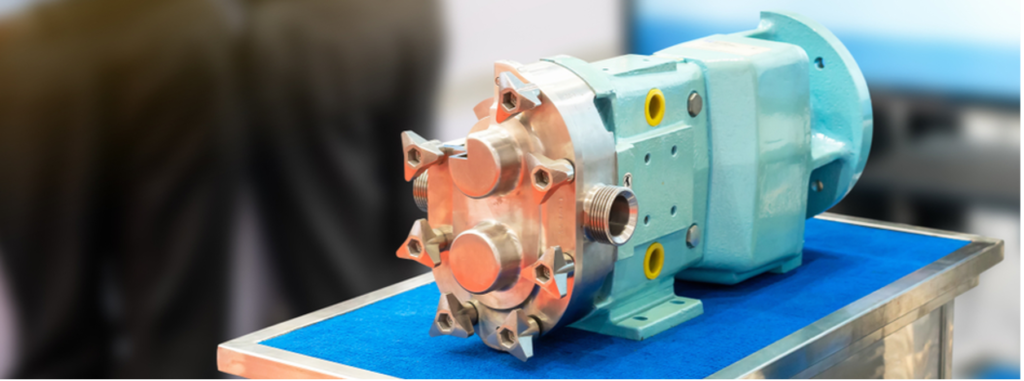

Lobe Pumps

Lobe pumps are used in various industries, including chemical, pharmaceutical, municipal, food and beverage, and even biotechnology. They are often used in sanitary applications because they are easy to clean and sterilize. They are also beneficial for transporting various forms of greases, bio-solids, and sludge. Lobe pumps prevent their rotors from coming into contact with each other by using timing gears. As a result, they are more shear sensitive and tolerant of solids.

Progressive Cavity Pumps

Progressive cavity pumps use a single-end, single-rotor arrangement. This leaves two cavities formed at the suction end of the stator. As one opens, the other closes to effectively maintain a consistent flow rate with minimal pulsation. These kinds of positive displacement pumps help move highly viscous fluids across long distances. For example, they are used for wastewater applications to move viscous slurry and sludge-containing solids.

How Positive Displacement Pumps Work

Positive displacement pumps can use a reciprocating, rotary, or diaphragm system to move fluid into a pump chamber. The pumping process is a repeating cycle that is known to generate consistent flow rates. While these pumps can move various types of fluids, they are generally used for viscous liquids and fluids that contain suspended or fragile solids.

To make a fluid move, a positive displacement pump draws a fixed amount of fluid into an inlet valve and displaces it into an outlet valve. Unlike centrifugal pumps, they do not reply on impellers. Instead, they use rotating or reciprocating parts to push the fluid directly into an enclosed cavity. Once enough pressure builds up, the liquid moves into the discharge system. As a result, a positive displacement pump’s fluid velocity is much lower than that of a centrifugal pump.

Finding Pumps and Spare Parts

At DXP, we are dedicated to providing the highest-quality positive displacement pumps and parts for all of our customers! We offer the best industrial solutions for your needs, from horizontal pumping systems to specialty pump designs. Our pump experts are available around the clock to keep your equipment running in prime condition. In addition, we offer pump service and repair, spare parts, remanufactured pumps, and more. DXP is the leading rotating equipment supplier in the industry.

Contact us online today to learn more about our full range of industrial pump solutions.