6 Tips for A Successful Carbon Capture Project

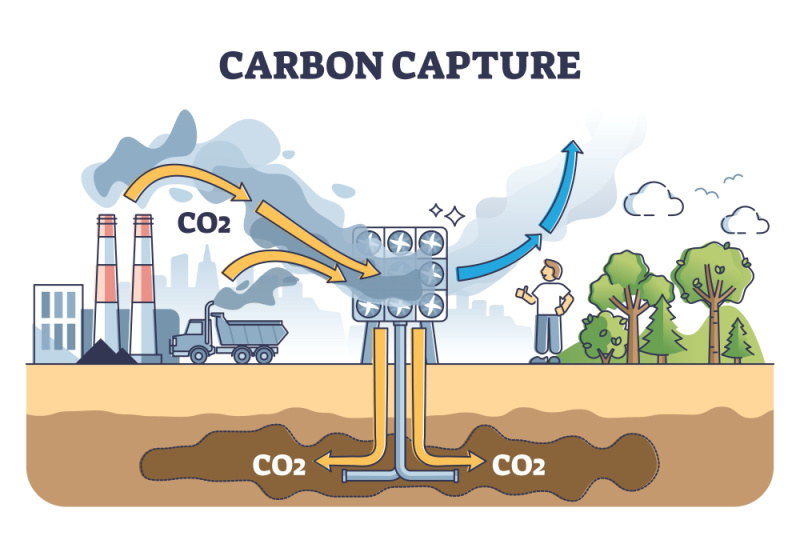

Carbon capture and sequestration is a widely discussed topic globally due to the growing need to minimize global warming and greenhouse gas emissions. This article overviews the technology and highlights some tips and considerations for carbon capture projects.

The Science Behind Carbon Capture

Operators must account for the large real estate requirements of CO2 absorption technologies when designing their carbon capture projects. Thus, equipment sizes and utility needs significantly impact the overall financial implication of the project, which is generally high.

Carbon capture and storage (CCS) is a viable technology for preventing the release of carbon dioxide (CO2) into the atmosphere, theoretically allowing the continued use of fossil fuels on a large scale. This technology is borne out of the growing need to minimize CO2 emissions and mitigate the effects of global warming. Unlike the conventional flue gas disposal methods, CCS can effectively separate CO2 from waste gases and transport it to underground storage through a process known as sequestration.

The three commonly discussed types of carbon capture include pre-consumption, post-consumption, and oxyfuel combustion carbon capture.

- Pre-combustion carbon capture enables the separation of CO2 from fossil fuels before combustion with high-pressure steams. This carbon capture type fosters the transition to hydrogen-based fuels.

- Post-combustion carbon capture enables CO2 separation after fossil fuel combustion due to difficulties in retrofitting already-existing plants.

- Oxyfuel combustion carbon capture leverages oxygen-rich combustion to maximize high-efficiency carbon capture.

Which Industries Utilize Carbon Sequestration Projects?

Various industries incorporate carbon capture sequestration projects into their operations to contribute to the efforts to address global warming. For example, the natural gas processing industry currently embarks on the most carbon capture projects globally. During natural gas processing, operators minimize the CO2 levels to send more refined and high-purity gas to end users. Some other industries that implement CO2 capture projects include:

- Chemical production

- Hydrogen production

- Fertilizer production

- Steel production

- Concrete/cement production

- Power generation

Since carbon capture, particularly pre-combustion carbon capture, produces significant amounts of hydrogen gas, fertilizer production, which is hydrogen-intensive, can benefit from the process. Moreover, the steel and concrete/cement production industries generate substantial amounts of CO2. Therefore, carbon capture and sequestration projects are increasingly necessary to curb excessive CO2 emissions from these industries.

Best Candidates for Carbon Capture Projects

Captured carbon must be transported and stored to ensure its emission into the environment. Consequently, operators must identify suitable sites for carbon capture and storage projects to reduce the global CO2 footprint. Some potential candidates for CO2 sequestration include saline aquifers, depleted gas reservoirs, and enhanced oil recovery (EOR) sites.

Saline Aquifers

Saline aquifers are rock layers that store saltwater deep underground. These underground reservoirs commonly comprise porous and permeable rocks containing portable water at the top and non-portable ones deeper underground. Saline aquifers are the most suitable reservoirs for carbon capture since they allow supercritical CO2 to float up to the impermeable rock layers and slowly dissolve into the saline water. Eventually, the CO2 sequestrates within the aquifer.

Depleted Gas Reservoirs

Depleted gas reservoirs serve as suitable CO2 storage since the rock pore spaces previously containing oil and gas resources can adequately cater to captured carbon. These depleted reservoirs become under-pressured due to hydrocarbon extractions, making them safe for CO2 sequestration projects. In addition, depleted reservoirs can contain more quantities of CO2 and other fluids than the extracted hydrocarbon fluids due to varying fluid properties. Carbon sequestration projects involve injecting saline water into the reservoir and pumping CO2 until it reaches a predetermined pressure. After the sequestration is complete, operators cap or plug the reservoirs and ensure prolonged monitoring of the reservoir and reservoir integrity.

Enhanced Oil Recovery (EOR) Sites

EOR includes the process of CO2 injection into producing oil reservoirs to increase its overall pressure and ensure increased productivity of producing wells. The CO2 reduces the viscosity of crude oil, allowing for more efficient movement and collection of the hydrocarbon fluid. The process enables CO2 sequestration while improving oil recovery, maximizing the efficiency of both operations.

6 Things to Consider When Planning Your Carbon Capture Project

Operators must make a few considerations when planning carbon capture and sequestration projects. Some of these considerations include:

- Instrumentation and Monitoring

- Transportation Infrastructure and Disruptions

- Equipment and Structural Foundation Requirements

- Technology Reliability

- Community Acceptance

- Long-term Project Considerations

1. Instrumentation and Monitoring

Although liquefied CO2 is not corrosive to conventional pipeline fabrication materials, such as ordinary carbon steel, the presence of water moisture and other impurities, including hydrogen sulfide (H2S), could present a corrosion hazard. Thus, proper monitoring and safeguards, including upgrading to austenitic 316 stainless steel, can significantly minimize the likelihood of such a hazard. Moreover, monitoring CCS with instrumentations, such as analyzers, flowmeters, and interlocks, can identify and eliminate the transmission of off-spec CO2.

2. Transportation Infrastructure and Disruptions

With proper risk assessment and management strategies, operators can account for potential disruption and safety mishaps in CO2 transportation. Incorporating warning systems and industrial safety measures into CO2 sequestration projects is essential for the overall safety of workers and the environment. Additionally, operators must prioritize transportation infrastructure with minimal human interaction, fewer risks, and ample ventilation in the event of tank car and truck transport.

3. Equipment and Structural Foundation Requirements

Operators must account for the large real estate requirements of CO2 absorption technologies when designing their carbon capture projects. Thus, equipment sizes and utility needs significantly impact the overall financial implication of the project, which is generally high.

4. Technology Reliability

While new CCUS technology lacks data on reliability, older technologies may be obsolete. Thus, operators must balance reliability and obsolescence to identify the ideal carbon capture and sequestration technology for their project in light of prevalent conditions.

5. Community Acceptance

Another top consideration for CCS projects includes community acceptance. Although carbon capture has several benefits to the environment, the community may have several concerns, including long-term noise levels, odor, amine emissions, etc. Thus, operators must address these concerns to improve community acceptance and increase trust in their environmental stewardship.

6. Long-term Project Considerations

Operators must consider the long-term impact of CCS projects on the environment. After addressing. There must be supply chain robustness, CO2 market, disposal contractor stability, and environmentally advanced technology supplier considerations before starting carbon capture and sequestration projects.

Planning A Carbon Capture Project? IFS Can Help

IFS is dedicated to providing clients with best-in-class carbon capture, transportation and sequestration solutions. Our advanced CCUS oil and gas services are ideal for meeting consumer and industry requirements for carbon capture, utilization, and storage.

Please contact us today for further information about our products and services.