How to Save Energy with Synchronous Belt Drives

One little known way to enhance energy efficiency in your operations is by using synchronous belt drives. These belt drives offer significant energy savings compared to traditional V-belts, contributing to reduced operational costs and a smaller carbon footprint.

What Are Synchronous Belt Drives?

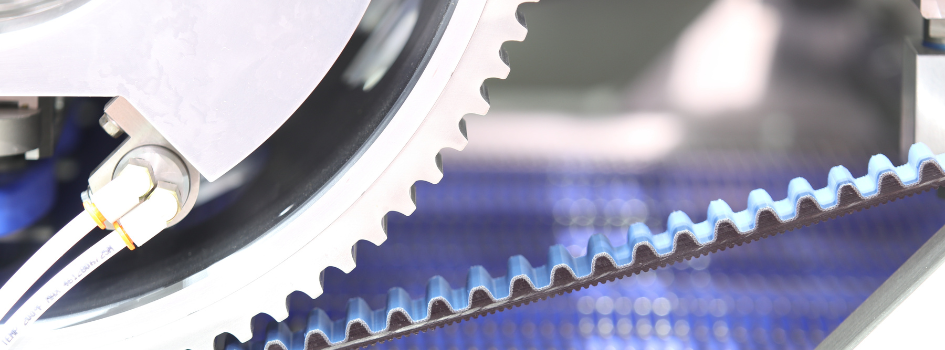

Synchronous belt drives, also known as timing belt drives, are a type of belt drive system that transmits power through the engagement of teeth on the belt with corresponding grooves on the pulleys. This positive engagement ensures no slippage, providing precise and efficient power transmission.

How it Works

Synchronous belt drives work by using a belt with teeth that mesh precisely with corresponding grooves on the pulleys, ensuring positive engagement and eliminating slippage. As the driving pulley, connected to a power source like an electric motor, rotates, it moves the belt, which in turn rotates the driven pulley.

This mechanism allows for efficient and accurate power transmission, with efficiency typically ranging from 98% to 99%. The teeth on the belt distribute the load evenly, reducing stress on individual components and enhancing durability, making synchronous belt drives ideal for high-torque applications and those requiring precise timing.

How Synchronous Belt Drives Save Energy

1. High Efficiency

The high efficiency of synchronous belt drives means that more input energy is converted into useful work — rather than being lost as heat due to slippage or friction. According to a U.S. Department of Energy study, synchronous belts can save up to 5% energy compared to V-belts in industrial applications.

2. Consistent Performance

The lack of slippage ensures that the performance remains consistent over time, avoiding the gradual energy loss that can occur with worn or poorly maintained V-belts.

3. Optimal Load Distribution

The design of synchronous belts allows for more even load distribution, which reduces the strain on individual belt components and leads to more efficient operation.

Synchronous Belts vs. V-Belts

The main difference lies in the engagement mechanism. Synchronous belts have teeth that engage with grooves on the pulleys, preventing slippage and ensuring more efficient power transmission. V-belts rely on friction, which can lead to slippage and energy loss.

Benefits of Synchronous Belt Drives

- Energy Efficiency – Synchronous belt drives are known for their high efficiency, typically between 98% and 99%. This efficiency is due to their positive engagement mechanism, which minimizes energy losses from slippage and friction.

- Reduced Maintenance – Unlike traditional V-belts, synchronous belts require less frequent tension adjustments and replacements, leading to lower maintenance costs and downtime.

- Extended Service Life – Synchronous belts are designed to last longer, often outlasting V-belts by a factor of two to three times. This longevity reduces the frequency of belt replacements and contributes to overall cost savings.

- Noise Reduction – These belt drives operate more quietly than V-belts, which can contribute to a better working environment and reduce noise pollution.

Implementing Synchronous Belt Drives

- Assess Your Current System – Evaluate your existing belt drive systems to identify potential areas for improvement. Consider factors such as energy consumption, maintenance costs, and operational efficiency.

- Choose the Right Belt – Select the appropriate synchronous belt for your application. Factors to consider include load requirements, operating environment, and compatibility with existing equipment.

- Professional Installation – Ensure that the belt drive is installed correctly by a qualified technician. Proper installation is important for maximizing the efficiency and lifespan of the belt drive system.

- Regular Monitoring and Maintenance – Even though synchronous belts require less maintenance than V-belts, regular inspections are still necessary to ensure optimal performance. Check for signs of wear and tear and replace belts as needed.

FAQs About Synchronous Belt Drives

Can synchronous belts be used in high-torque applications?

Yes, synchronous belts are well-suited for high-torque applications due to their positive engagement and robust design.

How often should synchronous belts be inspected?

While they require less frequent maintenance than V-belts, it is still recommended to inspect synchronous belts regularly, at least every six months, or as specified by the manufacturer.

Are there specific environmental conditions that affect synchronous belt performance?

Synchronous belts can operate in many types of conditions. But, extreme temperatures, exposure to chemicals, and abrasive environments can impact their performance and lifespan. Always choose belts rated for your specific operating conditions.

Save Energy with DXP’s Synchronous Belt Drives

At DXP, we offer a comprehensive range of synchronous belt drives tailored to your specific needs. Our industrial distribution experts are here to help you select, install, and maintain the best solutions for your operations.

Contact Us Today

Discover how DXP can help you save energy and optimize your industrial processes. Contact our team for more information about our supply chain solutions.