Gland Seal vs. Mechanical Seal – What’s the Difference?

When it comes to deciding on the best sealing solution for your pumps or agitators, newer developments in sealing technology offer more options than ever before. Although gland or packing seals have been the default sealing method of choice for many years, mechanical seals provide many operational benefits and should also be considered.

Here is a comparison between gland packing and mechanical seals, and how you can decide which one is right for you.

Difference Between Mechanical Seal and Gland Packing

Packing seals have been the most widely used sealing solution for many years. Packing seals use rope-like materials that wrap around the shaft of a pump, filling in dead space and minimizing fluid loss. Over time, however, fluid loss will increase as the gland packing material begins to wear down and may impair regular lubrication or reduce ease-of-replacement that is required to function properly.

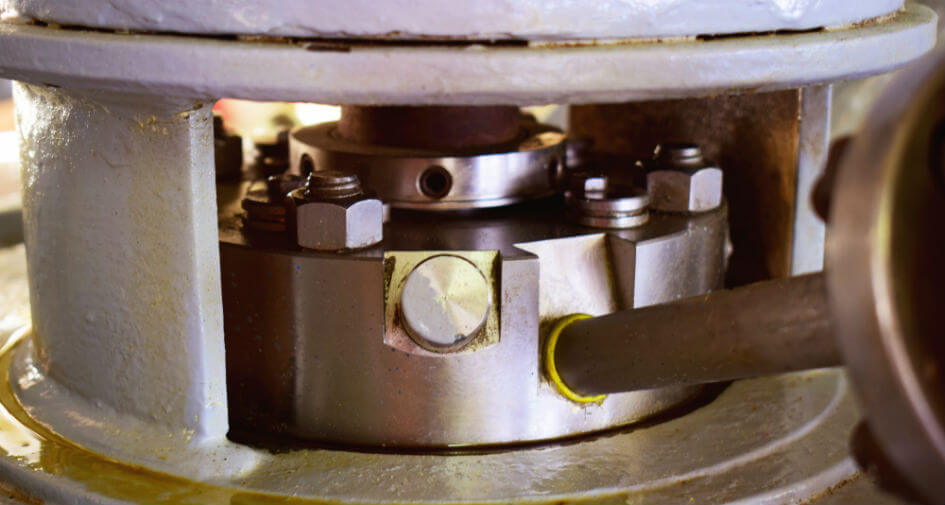

Mechanical seals are preferred over traditional packing seals in diverse applications during which leakage problems should be avoided. Mechanical seals are more durable than their predecessors and are designed to take much more punishment. Basic mechanical seals use multiple sealing points to nearly eliminate any leakage issues.

While one sealing point stays fixed, another rotates with the shaft. Fluid leakage is stopped by either a wedge, V-ring or O-ring as the lapped faces collapse.

Whether you’re considering mechanical seal vs. packing seal solutions, look to DXP. We act as both mechanical seal suppliers and packing seal suppliers depending on what your situation requires.

When Should You Use Packing Seals?

Packing seals are typically the most economical choice for sealing solutions, which is why they still widely used. They are also easier to install than mechanical seals. Packing seals don’t require that you decouple the drive shaft, leaving a considerably shorter installation time than other types of seals.

Packing seals are also a bit more forgiving than mechanical seals. While pumps and agitators have large amounts of radial movement and a higher chance of misalignment, packing seals can adapt to the conditions and maintain their integrity.

A good example of an industry where packing seals are preferred is mining and ore processing, where packing seals are the economic choice and able to adapt to the large shaft movements and equipment sizes.

When Should You Use Mechanical Seals?

Mechanical seals are the ideal choice when seal leakage is not an option for equipment or applications. This is usually the case when pump leakage can cause environmental or safety issues. Mechanical seals are much more durable than packing seals and are the better choice for long-term operation of your pumps.

Although mechanical seals can be costlier than packing seals, they are a great investment that can save you the costs of constant packing seal repairs and replacements. When considering gland packing vs mechanical seal solutions, mechanical seals are the best for minimizing sleeve damage. Packing seals are removed and replaced much more often than mechanical seals, which causes considerable wear and tear to the pumps as they are disassembled and reassembled.

When choosing the sealing option that’s right for your applications, mechanical seal and gland packing seal offer both pros and cons. You can search our list of seals and gaskets to find the solution works best for your business. Whether your decision is based on sourcing the highest-quality solution or the most economical, DXP can meet the needs of your application.

Contact us today for more information about our sealing solutions.