Save Energy & Costs with IsoBoost

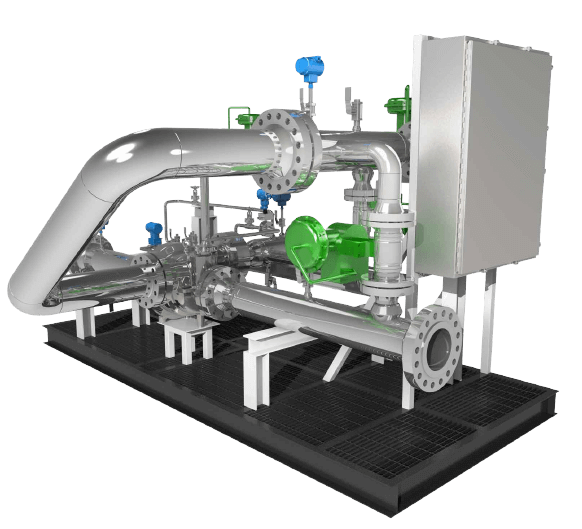

IsoBoost is a hydraulic system that recovers pressure energy, reduces power consumption and increases the reliability of pumping systems.

By replacing a pump and motor system with the simple and efficient IsoBoost, plants can expect millions of dollars in energy savings and a big drop in maintenance over the life of a plant.

With IsoBoost, plants save up to 50% of electric power costs.

The core of IsoBoost is a proprietary liquid-to-liquid turbocharger. With three times the reliability of a traditional pump, the turbocharger recovers energy from the letdown of a high-pressure fluid and transfers it to a low-pressure fluid to reduce the energy required for pumping.

– Save with Sour Gas Removal

– Target CO2 Removal

– Reduce Grid Reliance

IsoBoost Benefits

- Save energy – Reduce plant operation costs

- Improve reliability, availability, maintainability

- Lower carbon footprint and emissions to comply with regulations

- Explore new options in plant design

- Mitigate risk of electricity price fluctuations

IsoBoost Features

- 10 year mean time to failure (MTTF) three times the 2.9 year MTTF of a typical high pressure pump

- Up to 80% efficiency

- Always at best efficiency point (BEP) within operating range

- Only one moving part

- No shafts exiting the casing

- No Shaft seals, no seal leaks possible

- No seal support systems

- No alignment required

- Bearings self-lubricated by process fluid

- No external oil lubrication systems

- Rotating assembly speed unconstrained and self-regulating

- Very low vibration

Plants can save up to 50% of total electric power consumption for the acid gas removal circuit.